产品说明

现货促销,详细请致电18618101725(微信)

MesoBioTech通过合理设计和标准化制造微流控芯片,自动控制器和配件,专注于集成解决方案。 这些解决方案应适用于各种各样的应用程序,从而损害其简单性,灵活性,多功能性和前景:

-

通用微流控产品

-

即插即用的微流处理集成芯片

-

补丁和filtres可逆组装集成芯片

-

流量控制器,用于多功能流量开关和调节

-

用于流连接,切屑夹紧等的附件

-

基于干细胞的检测产品

-

单层纳米纤维培养贴片

-

用于细胞自动处理的培养控制器

-

使用人多能干细胞的组织贴剂

-

片上器官进行集成建模

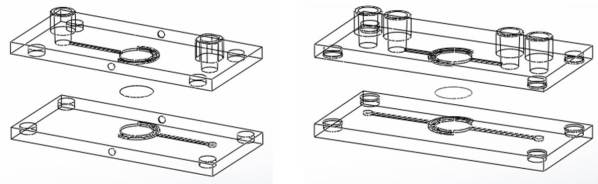

一、INTEGRATION CHIPS

INTEGRATION CHIPS

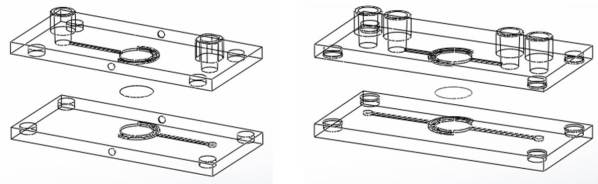

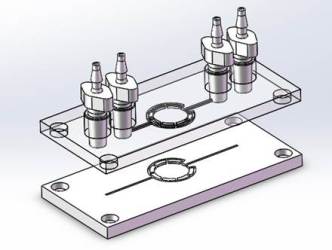

The integration chips are formed with two plastic plates, each having an elastomeric thin film to ensure good sealing when clamped. They are typically used for patch and filter integration for which micro-chambers and micro-channels are predefined in both plastic plates.

For filtration, one inlet (outlet) channel is patterned on the upper (lower) plate with a Luer connector. An elastomeric thin film with some removed areas can be added to improved the sealing. Similarly, inlet and outlet chambers are patterned in both plates for organ on-a-chip applications. When a tissue patch is placed between the two plates, culture media containing different factors can flow in the upper and lower chambers separated by the patch so tissue model such as skin, alveolar, stomach, brain-blood are envisaged.

Good sealing is achievable with a loose-leaf clamp or screw enhanced assembling. After fluidic processing with the chip, the integrated elements can be released for other operations.

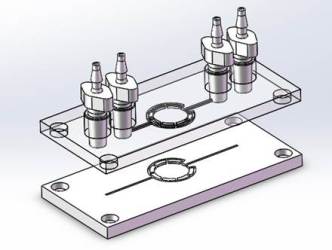

二、INTEGRATED CHIPS

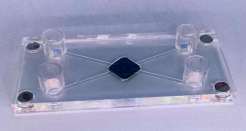

Example of integrated chip with Luer connectors

Integrated chips are manufactured by mass production. The basic element of the chip (upper part) is a plastic plate with standard Luer connectors and an elastomeric thin film for conformal contact with the lower part in which microfluidic circuits can be patterned. While the lower part can be a sheet in plastic, elastomeric, glass, silicon or other materials, standard elements such as mixing Y-channels, gradient Xmas trees, droplet generators, etc. can be patterned. The upper and the lower part of the chip can be reversely or irreversibly assembled.

With a simple mechanic clamp, good sealing is achievable. Otherwise, MesoBioTech offers irreversibly assembled devices for common uses.

三、FLOW CONTROLLERS

Front-back panel of flow controller model FC-PVL3 (left) and FC-HP1 (right).

Model FC-PVL3 is an integrated system for general microfluidic processing. It is composed of built in pump, vacuum pump, solenoid valves, pressure regulators, rotary valve and pressure sensors. It also has 5V, 12V and 24V outputs, analog inputs and outputs as well as RS232 and TTL serial communication interfaces which controls external elements.

Model FC-HP1 is a microfluidic controller with high precision pressure regulation. It is composed of built in pump, solenoid valves, high precision pressure regulators, and pressure sensors. It also has 5V and 24V outputs, analog inputs and outputs as well as RS232 serial communication interfaces which controls external elements.

Offline operation: All internal and some of the external elements can be controlled with the front panel buttons and knobs. The user defined program sequences or algorithms can also be chosen for automatic operations.

Online operation: Computer programs in C++, Matlab or Android are prepared with appropriate graphical interface to facilitate the control and monitoring or to download program sequences or algorithm into the apparatus for offline operations.

Network operation: The remote control is feasible with Bluetooth, wireless or Ethernet using smartphones, tablets and other terminals. In addition, they can easily communicate with other MesoBioTech instruments and commonly used devices such as NI-Daq modules, CCD cameras, spectrometers, electrochemical station, etc. for monitoring or feedback control. Finally, MesoBioTech provides open sources or SDK for uses’ development.

Configuration and specifications of Model FC-PVL3

-

Air pump (4 mbar – 0.9 bar, noise < 65 db)

-

Vacuum pump (-0.5 bar – 4 mbar, noise < 65 db)

-

4 electronic pressure regulators (accuracy ± 1 mbar)

-

8 solenoid valves (response time 0.1 s)

-

2 release valves (response time 0.1 s)

-

10 channel rotary valve (response time 1 s)

-

8 voltage (12V ) outputs

-

6 analog outputs inputs

-

1 TTL serial output

-

2 RS232 connectors with 5V, 12V and 24V supply

-

Bluetooth and wireless module

-

4KB EPPROM (for numerical sequence storage)

-

1G SD card memory (for data storage)

-

User graphical interface

-

Gas flow 0-1.1 L /min

-

Liquid flow rate 0-10 ml / min

-

Weight: 4.5 kg

-

Size: 27.5 × 25 × 11 cm

Working conditions

-

Power: 12V-4A DC or portable power

-

Temperature range: 10-50 ℃

-

Humidity range: 20-80%

-

Minimum PC configuration: Intel Core i5-4xxx, 4G memory, Win7, USB 2.0

-

Support software: c++, Matlab, Android, Arduino

Optional accessories

-

Sensirion flow-meters

-

Solenoid valves

-

Rotary valve

-

Liquid distribution valve

-

Low noise pressure source (2 bar, -1 bar, noise < 40 db)

-

Fast CCD camera

-

Microscope stage

-

Optical spectrometer

-

Electrochemical station

References:

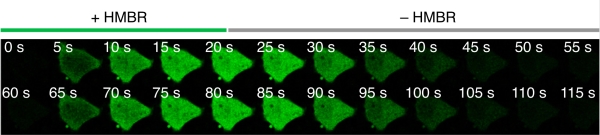

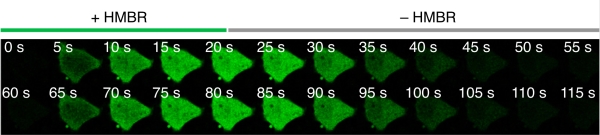

“Small fluorescence-activating and absorption-shifting tag for tunable protein imaging in vivo”, Proc Natl Acad Sci U S A. 2016 Jan 19;113(3):497-502.

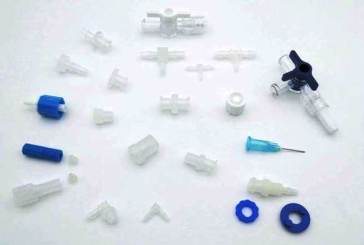

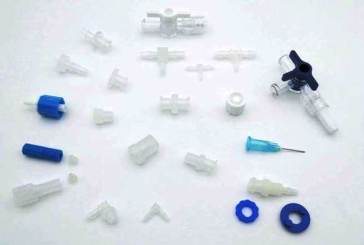

四、FLUIDIC ACCESSORIES

MsoBioTech provides patent protected accessories for general microfluidics and stem cell devices, including

-

Bottle caps: Typically, a metallic female thread and a female Luer are embedded respectively in the center of and aside a bottle cap. Caps with 5 female threads is also available. These female threads are compatible with the commonly used fluidic connectors such as female Luer with barb panel mount and bulkhead, female Luer with male thread, flat-bottom nuts with ferrule, etc.

-

Chip clamps: Including i) Hand screw open-clamp, ii) Hand screw close-clamp, iii) Inox loose-leaf clamp, and iv) Hand screw multiple open-clamps (patent protected). Good sealing can be achieved with our elastoplastic chips.

-

Patch handling device for Boyden chamber like cell based assays with 2 inch dish and 6 well plates.

-

Luer connectors and tubes: They are selected for various routing work with MesoBioTech chips and instruments.

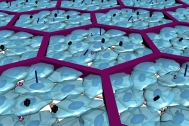

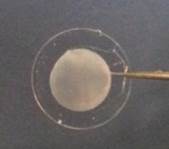

五、CULTURE PATCH

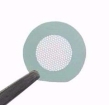

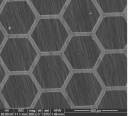

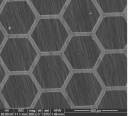

Culture patch with monolayer nano-filers on a frame

Culture patch is a device of monolayer nanofibers deposited on a patterned microframe. It is morphologically and materially in-vivo like extracellular matrix. Typically, it is used for off-ground cell culture. When used for culture and differentiation of human pluripotent stem cells, it allows minimizing the exogenous contact and increasing the nutrient uptake as well as the tissue organization. It is compatible not only with the conventional tools such as culture dish, multi-wells and Boyden chambers but also with advanced assay.

Boyden chamber  Culture patch  Aligned fibers  Cells on a patch

Specifications:

Depending on applications, we provide cell patch with different configurations and made of different kinds natural biomaterials or synthetic biodegradable polymers listed in the table:

|

Culture Patch

|

Parameters

|

|

Patch size

|

13, 25, 37,47mm

|

|

Nanofibers material

|

Gelatin, Collagen, PLGA

|

|

Nanofibers diameter

|

100-500 nm

|

|

Nanofibers thickness

|

<1um

|

|

Porosity

|

60-80%

|

|

Frame materials

|

Epoxy, PEGDA, PLGA, Gelatin

|

|

Frame structures

|

Circle, Honeycomb

|

|

Micropattern size

|

200, 500,1000um

|

|

Frame thickness

|

20, 50, 100um

|

Application:

-

Mammalian cell culture

-

hiPSC culture and differentiation

-

Tissue formation

-

Organoids formation

-

Drug discovery

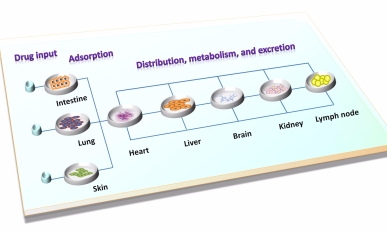

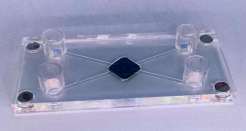

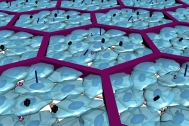

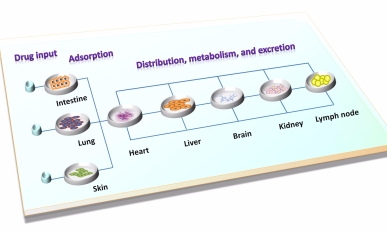

六、ORGAN ON-A-CHIP

Microfluidic device for patch integration

Integration of a tissue patch into a chip gives rise to organ on-a-chip models. Typically, a tissue patch made two types of cells are inserted in the interface of two elastoplastic plates. After clamping, solutions are injected to create physiological conditions.

One examples is alveolus modeling. By differentiating hiPSCs into epithelial and endothelial cells on upper and lower side of a culture patch, an alveolar tissue is obtained and then integrated into a microfluidic devise to recapitulate the pulmonary physiological conditions. By injecting cell factors and/or nano-materials, it is possible to study the translocation effect at the alveolar epithelium level.

Organ on-a-chop model with different tissue patches

More generally, integration of several tissue patches of different cell types into a microfluidic system will allow creating a body-like circulatory or micro-physiological system to investigate the mutual influences of different tissues. For example, one can co-culture of human intestine, liver, skin and kidney cells with a medium circulation loop for drug testing.

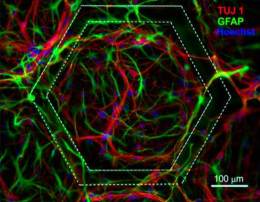

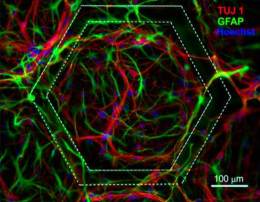

七、TISSUE PATCH

Tissue patch

Tissue patches are mostly derived from human induced pluripotent stem cells (hiPSCs). By changing the culture parameters, flat and hemisphere colonies are generated in each of the honeycomb compartment. Homogeneous cardiac and neuron tissues are produced, showing up-regulated gene expression of the specific proteins and regular beating or spontaneous firing.

When placed on a multi-electrode array, characteristic drug responses are observed. Tissue patches of co-cultured two cell layers are available, enabling different tissue models. More sophisticated tissue patches are also obtainable for three-dimensional tissue modeling.

Embryoid body of hiPSCs Embryoid body of hiPSCs

.

Neurons and astrocytes on patch Neurons and astrocytes on patch

八、CULTURE CONTROLLER

? Culture Controller? is a prototype for long-term culture and differentiation of human induced pluripotent stem cells (hiSPCs). It is designed for in-vivo mimicking of nutrient feeding in a perfusion-diffusion regime. It allows reducing time and laborious efforts as well as risks of contamination.

Control Unit

Typically, a ?Culture Controller? is composed of a central unit to control micro-flow processing, a culture unit placed in an incubator and a cold unit to store and supply culture media with selected factors. The whole hiPSC differentiation processes can then be programmed with minimum human intervention and good reproducibility.

The center unit of the system can also be combined with other fluidic element, allowing automated cell sorting, labeling, SEM sample preparing, etc.

The system is applicable to both dish and chip based assays as well as Culture Patch and Tissue Patch developed by MesoBioTech. More sophisticated culture systems are under exploration.

Culture Unit

|

Example of integrated chip with Luer connectors

Example of integrated chip with Luer connectors

Boyden chamber

Boyden chamber Culture patch

Culture patch Aligned fibers

Aligned fibers Cells on a patch

Cells on a patch

Embryoid body of hiPSCs

Embryoid body of hiPSCs

Neurons and astrocytes on patch

Neurons and astrocytes on patch

Control Unit

Control Unit

Culture Unit

Culture Unit