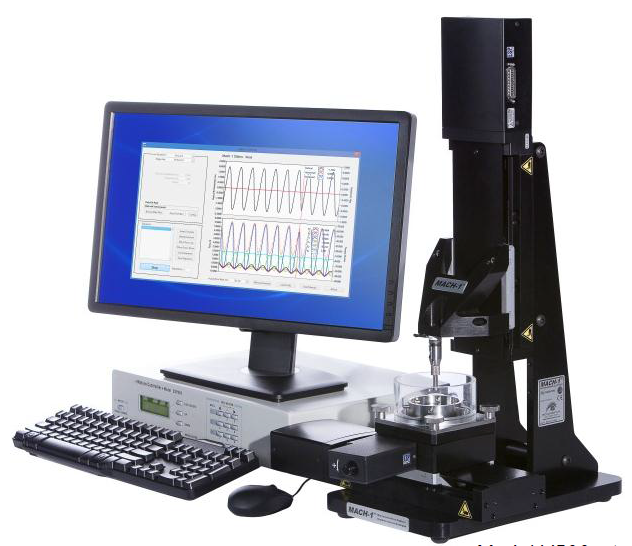

MachOneTM micromechanical testing system

Model: MachOne V500c, MachOne V500cs, MachOne V500ct, MachOne V500css, MachOne V500cst, MachOne V500csst

Sales representative: Baohua Chen

Phone:86-010-67629703

Email:chenbaohua@bio-goods.com

Manufacture: Inc.

Made in Canada.

Thank you for your interest in products.

Bio Excellence international Tech Co.,Ltd has been acting as distributor for the sale of products since 2019. Bio Excellence can provide free technical guidance for tension, compression, indentation and user site installation&training, until the user can use them independently. The test material includes from soft lung tissue to bone tissue material. If you have any questions, please do not hesitate to contact us.

manufactures and commercializes testing devices for the mechanical characterization of biomaterials and cartilage. The Mach-1? multiaxial mechanical tester is the only all-in-one device designed for compression, tension, shear, friction, torsion and indentation mapping. The Mach-1? is used in many university labs and is deemed an excellent educational tool.

also offers a full-service approach to biomechanical testing. In addition to performing highly controlled tests using a state-of-the-art technology, its expert team adheres to effective Standard Operating Procedures, develops reliable testing protocols, and delivers accurate data analysis reports in compliance with Good Laboratory Practice.

Since 1999, `s unique multiaxial mechanical tester has helped hundreds of scientists around the world to enhance and publish their innovative research activities related to biomaterials, tissues and soft materials.

The MachOneTM multiaxial mechanical tester is the only all-in-one device designed for compression, tension, shear, friction, torsion and indentation mapping.

BENEFITS AND CARACTERISTICS

Mach-1?

?Upgradable and adaptable to a large variety of materials and test configurations

?Compatible with a wide selection of uniaxial and multi-axial load cells

?Large selection of popular accessories & infinite possibility of custom-designed accessories

?Comes with a computer (Windows 10 Pro, Acquisition card, Webcam, etc.) and software (MachOne Motion & MachOne Analysis)

?User-friendly software for effective data collection and simplified analysis

?Accurately characterizes specimens with low mechanical properties or with dimensions falling within the micrometer to centimeter range

?Robust design; Will keep its integrity for years

?Excellent educational tool for students - Unlimited access to our lab modules

?Does not require lubrication or complex maintenance

?Occupies little laboratory space – Easy to lift for convenient re-location (fits within a standard culture incubator)

?Complemented by a team of scientific experts

?Performs uniaxial high-precision testing in compression and tension, in various modes including dynamic, static, and waveform loading

?No PID adjustment required to account for material properties

?Is the only device able to perform 3D normal indentation on a surface that is not flat

?Is used by renowned scientists

?Supported by a 24-month hardware warranty

?Free software upgrades within 2 years of purchase

?Online support and training of lab assistant included

?Data can be imported into third-party software for further analysis

UNIQUE FEATURES

Upgradable

The Mach-1? has been designed to be easily upgraded with the addition of motorized stages, load cells and accessories, so it will evolve and constantly adapt to changes in your material research priorities.

3D Normal Indentation Mapping

Indentation usually requires the tested surfaces to be flat and it also requires the compression axis aligned perpendicularly to the articular surface. The 3D “Normal Indentation” function of the multiaxial mechanical tester MachOne v500css precisely detects the height and orientation of the surface at the XY position and records the load (multiaxial load cell) while simultaneously moving the three stages of the tester at different speeds to move a spherical indenter with a predefined displacement profile along a virtual axis normal to the surface of the sample.

This information comes from the link: https://www..com/contact/